Learn about HVAC Installation

Outline:

– Home assessment and load calculations

– Equipment types and efficiency metrics

– Ductwork, airflow, and indoor air quality

– Step-by-step installation and commissioning

– Costs, incentives, and maintenance planning

Assessing Your Home and Calculating the Right Load

The foundation of successful HVAC installation is a precise load calculation tailored to your home’s unique envelope and climate. Rather than relying on rules of thumb, a structured approach considers orientation, insulation levels, window performance, air leakage, occupancy, internal gains, and local weather data. The goal is to determine both sensible (temperature) and latent (moisture) loads for peak conditions, so equipment capacity aligns with demand without oversizing. Oversized cooling short-cycles, leaving humidity behind; undersized systems run constantly, still missing target temperatures on extreme days. Thoughtful assessment avoids both pitfalls, keeps noise and drafts down, and reduces energy use.

Start by characterizing the envelope. Attic R-values, wall assemblies, and window U-factors materially influence heat flow. In warmer climates, solar gain through west-facing glass can dominate load; in colder regions, infiltration and basement insulation might matter more. An energy audit, blower door test, and duct leakage check transform assumptions into measured facts. With those inputs, a room-by-room cooling and heating load profile emerges, guiding equipment selection and duct sizing. Key metrics help you think through efficiency and performance: SEER2 and EER2 describe cooling efficiency under seasonal and steady conditions; HSPF2 and COP speak to heat pump heating performance; AFUE reflects furnace fuel conversion efficiency.

Example: a 2,000‑square‑foot home in a mixed climate may require anywhere from 2 to 4 tons of cooling depending on envelope quality, glazing, shading, and infiltration. Rather than using square‑foot rules, verifying loads per room avoids hot and cold spots and illuminates where upgrades deliver outsized returns (e.g., attic air sealing before upsizing equipment). Useful planning checkpoints:

– Confirm design indoor conditions (e.g., 75°F, 50% RH for cooling; 70°F for heating).

– Reference local design temperatures to capture peak days, not averages.

– Validate ventilation needs to meet health guidelines and code.

– Decide early whether to prioritize dehumidification, low noise, or ultra‑low energy use.

Small refinements add up. Better attic sealing can lower required tonnage; shading western windows can trim peak gains; adding balanced ventilation can improve air quality without pressurization issues. A documented load calculation anchors the entire project, from equipment type to duct layout and control strategies, ensuring your investment delivers quiet, steady comfort across seasons.

Choosing Equipment and Configurations

With a load target in hand, the next decision is equipment type and configuration. The broad families include ducted split systems, packaged units, and ductless options, each with strengths that suit different homes and priorities. Heat pumps handle both heating and cooling, while furnace‑plus‑air‑conditioner pairs remain common where natural gas is prevalent. Variable‑speed compressors and modulating blowers provide finer control and steadier temperatures compared to single‑stage designs, which tend to cycle more. In humid climates, equipment that can slow airflow and extend runtimes often achieves better moisture removal.

Consider the home’s architecture and constraints. Ductless systems serve additions or retrofits where running ducts is impractical; ducted systems blend better with whole‑home distribution and filtration. For colder regions, select heat pumps with robust low‑temperature capacity and a clear heating performance map, or combine a heat pump with auxiliary heat for rare extremes. Efficiency ratings guide lifetime cost expectations: moving from a base efficiency to a higher tier reduces energy consumption, but the premium should be weighed against local utility prices and usage patterns. Controls matter as much as hardware; a well‑configured thermostat with humidity or staging control can unlock quieter operation and better comfort.

Trade‑offs at a glance:

– Ducted split systems: familiar, compatible with whole‑home filtration, flexible zoning; require careful duct design.

– Ductless: targeted comfort, no duct losses, straightforward retrofits; aesthetics and multi‑room coordination may need planning.

– Packaged units: compact footprint for limited mechanical space; exposure to weather can affect longevity.

– Variable‑speed and inverter technology: outstanding part‑load efficiency and comfort; higher upfront cost balanced by quieter, steadier performance.

In practical terms, match configuration to load profile and lifestyle. Homes with large internal gains benefit from equipment that modulates to track changing conditions. Households sensitive to noise gravitate toward variable‑speed fans, larger return paths, and generous filter areas. If indoor air quality is a priority, reserve cabinet space and static pressure for enhanced filtration and consider ventilation integration. When you align type, capacity, and control strategy, you set the stage for lower bills, fewer temperature swings, and a system that feels nearly invisible in daily life.

Designing Ductwork and Managing Airflow

Ductwork is the circulatory system of a ducted HVAC installation, and its design determines how quietly and efficiently conditioned air reaches each room. Proper sizing, short and smooth runs, and balanced supplies and returns keep static pressure within acceptable limits and ensure equipment can deliver design airflow. A common target is about 350–450 cubic feet per minute per ton of cooling, adjusted for humidity goals and coil characteristics. Exceeding allowable external static pressure strains motors, raises noise, and diminishes delivered capacity; undersized returns are a frequent culprit.

Layout strategy matters. Place returns strategically to avoid starving the blower, and provide transfer pathways for closed‑door rooms. Use gradual fittings rather than sharp elbows; limit flex duct to short, gently stretched runs with large radii; and rely on rigid duct where possible for low resistance. Duct leakage is hidden waste that can exceed 10% of fan airflow if left unchecked. Mastic sealant and mechanical fasteners outperform cloth “duct tape” over time. Filters must be sized to keep face velocity moderate—thicker, high‑area filters can capture more while reducing pressure drop.

Design checklist:

– Keep total equivalent length within targets for the blower’s capacity.

– Distribute supplies to wash exterior walls and windows in cooling-dominated climates, and to eliminate cold corners in heating seasons.

– Provide return paths for every major room or a measured undercut strategy plus central returns.

– Test and seal to a leakage rate aligned with local code or a stricter project goal.

Quantifying airflow during commissioning validates the design. Measure external static pressure and consult the fan performance table to confirm delivered CFM. Balance registers with dampers, aiming for room flows that track the load calculation, not just equal numbers across rooms. If a space still lags, re‑examine assumptions: insulation voids, unsealed can lights, or window infiltration can overwhelm even a well‑built duct system. When ducts are quiet, airtight, and right‑sized, comfort arrives without fan roar, drafts fade, and the system’s efficiency on paper becomes real in daily operation.

Installation Steps, Refrigerant Practices, and Commissioning

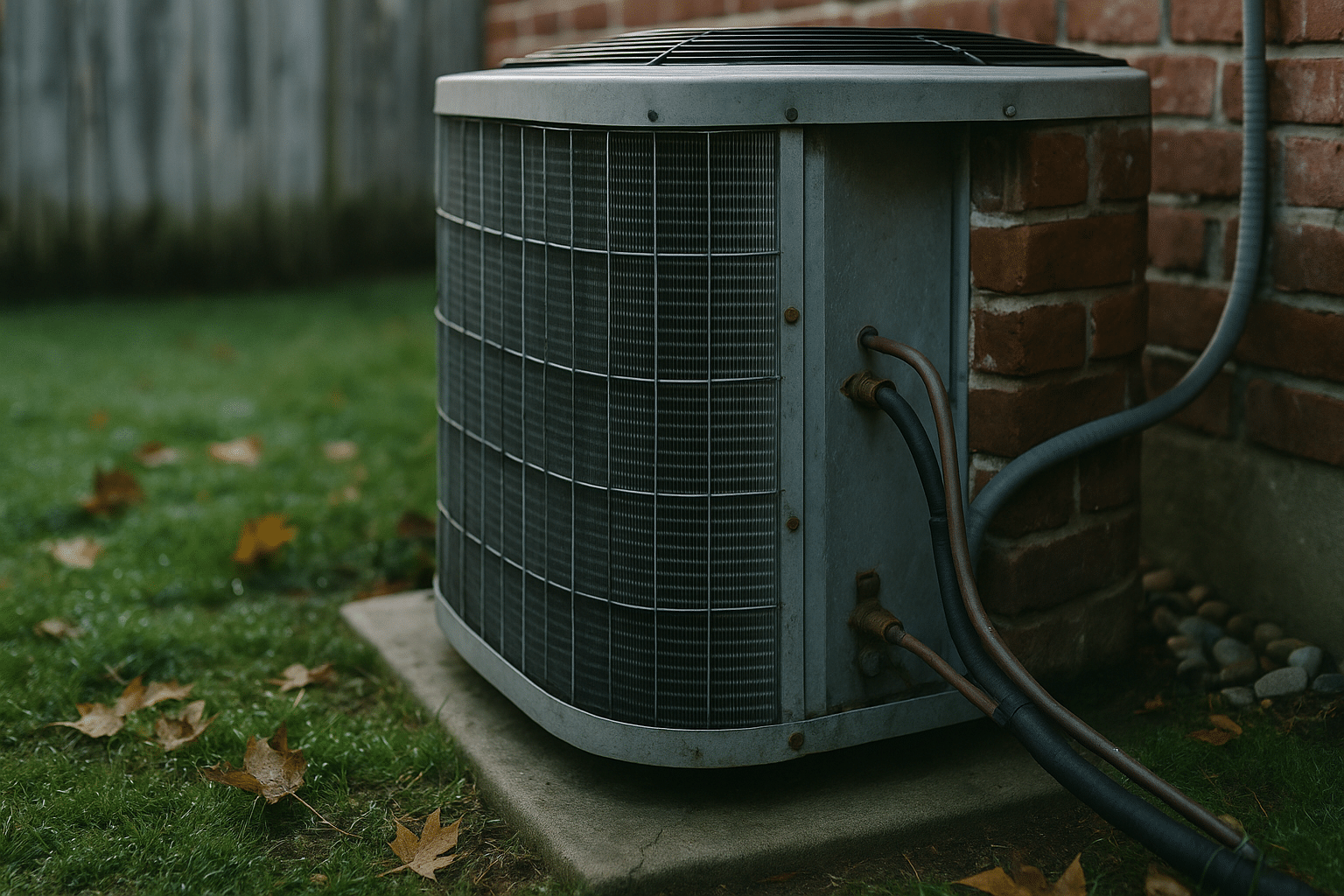

A tidy, code‑compliant installation turns a thoughtful design into reliable performance. Start with permits and a clear scope that covers electrical, condensate management, ventilation, and structural needs. Prepare the site: set a level, well‑drained pad for the outdoor unit with adequate clearance on all sides and above; protect line set routes; and plan for service access. Indoors, mount equipment so that filter changes and coil cleaning are convenient, and slope condensate lines with cleanouts and overflow protection. Confirm dedicated circuits, proper disconnects, and grounding before energizing anything.

Refrigerant piping demands care. Size lines to manufacturer specifications; keep runs as short as feasible; and avoid traps that invite oil pooling. When brazing, maintain a dry nitrogen sweep to prevent oxide scale inside tubing. Evacuate the system deeply—targets around 500 microns or better are common—and perform a standing vacuum test to reveal moisture or leaks. Charge by weighed methods when possible, then fine‑tune via superheat or subcooling to match outdoor conditions and equipment charts. For low‑GWP refrigerants, follow handling guidance and local rules, including ventilation in tight spaces if required.

Commissioning ties it all together. Verify airflow through external static pressure and temperature rise/coil drop checks; confirm supply and return temperatures track expected deltas at steady state. Validate controls: staging or inverter modulation, fan profiles for cooling and heating, humidity setpoints, and defrost logic for heat pumps. Calibrate thermostats, confirm sensor placement away from drafts and sunlight, and label shutoffs and service points. Document baseline data—amps, pressures, delivered CFM, and room airflow—so future maintenance has a clear reference.

Commissioning checklist:

– Confirm condensate drains with proper trap or factory design and test for leaks.

– Program blower profiles to favor dehumidification in sticky seasons when appropriate.

– Test safety devices: float switches, pressure protections, and lockouts.

– Educate occupants on filter changes, thermostat settings, and what normal operation sounds like.

A methodical install minimizes callbacks, protects equipment longevity, and ensures the comfort targets set during design show up in real life. The result is a quiet system that meets its efficiency promise and a homeowner who hears little more than the whisper of a balanced airstream.

Costs, Incentives, ROI, and Maintenance Planning

Project cost reflects a mosaic of decisions: equipment type and efficiency tier, duct complexity, electrical upgrades, ventilation integration, and site constraints. A modest replacement using existing ducts will land differently than a whole‑home redesign with zoning and new returns. Local labor rates and code requirements also influence totals. While it’s tempting to chase the lowest bid, a careful comparison that includes scope, commissioning steps, and warranty details often reveals why prices differ. A clear, itemized proposal with performance targets is worth its weight in avoided surprises.

Long‑term value comes from lifecycle cost, not just purchase price. Higher seasonal efficiency can trim cooling energy noticeably, and modern heat pumps with strong cold‑weather performance can displace a meaningful share of heating energy in many climates. An illustrative example: moving from a legacy cooling system with a seasonal rating near 10 to a contemporary unit around 15 represents roughly one‑third less energy for the same cooling output, though actual savings depend on usage hours, climate, and envelope quality. Incentives can improve payback: utility rebates for high‑efficiency equipment, potential tax credits where applicable, and low‑interest energy‑upgrade programs are common. Document model numbers and certified rating matches to qualify for such programs.

Maintenance planning protects the investment:

– Change or clean filters on a schedule appropriate to filter type and home conditions.

– Keep outdoor coils free of leaves, lint, and grass clippings; maintain clearances for airflow.

– Flush condensate lines and verify traps annually to prevent overflows.

– Schedule professional checkups to confirm refrigerant charge, electrical integrity, and safe operation.

Choosing a contractor is as important as choosing equipment. Ask for a written load calculation, duct design verification, and commissioning plan. Look for pressure readings, airflow targets, and documented baseline data in closeout materials. Request proof of permits and final inspection sign‑off when required. Red flags include rule‑of‑thumb sizing, skipping evacuation or nitrogen practices, and omitting airflow verification. Finally, register warranties promptly and keep manuals and installation reports together for future reference. With a measured approach to cost, incentives, and upkeep, your system can deliver steady comfort for years while using energy responsibly.