Learn about Solar Panels

Outline:

– How Solar Panels Work: Photovoltaic Basics and System Components

– Efficiency, Types, and Performance in Real-World Conditions

– Costs, Incentives, and Payback Math

– Installation, Siting, and Maintenance

– Environmental Impact and Future Trends

How Solar Panels Work: Photovoltaic Basics and System Components

Solar panels convert light into electricity through the photovoltaic effect, a neat bit of physics where photons knock electrons loose in a semiconductor and set them in motion. Most panels use silicon cells arranged in a grid, each cell built from two layers—one with an excess of electrons (n-type) and one with a deficit (p-type). When sunlight hits, an internal electric field pushes freed electrons in a single direction, producing direct current (DC). Because buildings run on alternating current (AC), a device called an inverter converts that DC into AC. The rest of the system—wiring, racking, monitoring, and safety hardware—bundles this conversion into a dependable, grid-synchronized power source. You can think of a solar array as a small power plant on your roof, quietly trading photons for kilowatt-hours while you make coffee.

Key parts in a typical residential setup include:

– Modules (panels): dozens of cells laminated under glass, framed in aluminum, sealed against weather.

– Inverter: string, micro, or hybrid units that convert DC to AC and manage grid interaction.

– Racking and attachments: rails, clamps, and roof or ground anchors that handle wind and snow loads.

– Balance of system: conductors, connectors, combiner boxes, junctions, rapid-shutdown devices, and monitoring.

– Optional storage: batteries for backup or time-of-use shifting, managed by a hybrid inverter or controller.

A few performance metrics help translate spec sheets into real-world expectations. Module efficiency indicates the fraction of sunlight converted into electricity; many modern monocrystalline modules reach roughly 19–23%, while some thin-film options sit closer to 10–13% but can perform well in low light or high heat. Temperature coefficient, commonly around -0.35 to -0.45% per °C above 25°C, explains why output dips on hot afternoons. Standard Test Conditions (STC) ratings describe laboratory output; Normal Operating Cell Temperature (NOCT) values are more realistic for outdoor operation. Over time, panels slowly degrade—often around 0.3–0.6% per year—so a decade-old system can still deliver the majority of its initial output. In short, photons in, electrons out, with a handful of components keeping the flow safe, steady, and grid-ready.

Efficiency, Types, and Performance in Real-World Conditions

Not all panels behave the same under the sun. Monocrystalline silicon modules are widely chosen for their high efficiency and compact footprint, while polycrystalline options, once common for budget-focused projects, have largely given way to more efficient designs. Emerging cell architectures, such as advanced passivated emitters or heterojunction structures, aim to reduce recombination losses and improve low-light response. Bifacial modules can harvest light from both sides, boosting output in reflective environments such as white roofs or ground surfaces with bright gravel. Thin-film technologies—based on alternative semiconductors layered on glass or flexible substrates—offer advantages in uniform appearance, certain temperature conditions, and weight-sensitive installations, though they typically trade maximum efficiency for those benefits.

Real-world performance hinges on more than cell chemistry. Factors include:

– Location and climate: A system near coastal fog will produce differently than one in a dry, high-irradiance plateau.

– Orientation and tilt: South-facing in the northern hemisphere tends to maximize annual energy, but east-west layouts smooth production across the day.

– Temperature and ventilation: Cooler modules are happier; a standoff from the roof that allows airflow can mitigate heat losses.

– Shading and soiling: Partial shade from trees, chimneys, or debris can disproportionately reduce output; module-level power electronics can help.

– System design: String sizing, inverter loading, and conductor losses all subtly shape the final production curve.

To put numbers on it, consider a 6 kW rooftop array. Annual output equals system size multiplied by available sun hours and tempered by losses. A quick way to estimate is via capacity factor (the ratio of actual to theoretical maximum). In a cloudy, northerly city, a residential rooftop might operate near a 13–15% capacity factor, yielding about 6,850–7,900 kWh per year. In sunnier, arid regions, capacity factor can approach 20–22%, producing roughly 10,500–11,600 kWh. Bifacial modules over bright surfaces or trackers in ground-mounted systems can push higher still, though trackers are seldom used on standard homes. The point is not to chase a single headline number but to align technology choice and layout with local conditions, roof space, and energy goals. When expectations are grounded in regional solar resources and sound engineering, the performance tends to match the forecast with satisfying accuracy.

Costs, Incentives, and Payback Math

Solar economics depend on equipment prices, labor, local policies, and your electricity rates. Installed residential costs often fall in a broad range, frequently around $2.50–$4.00 per watt in many mature markets, before incentives. Differences reflect roof complexity, system size, permitting requirements, and component choices, including inverter type and any battery integration. Operating costs are relatively modest; routine inspections and occasional cleaning typically add up to a small fraction of the initial spend. Over its life, a well-installed system may come in at a levelized cost of energy (LCOE) in the single- to low-teens cents per kWh, depending on sunshine, installation price, and financing terms.

Several policy tools can improve the picture:

– Upfront rebates: Reduce the initial invoice and may be tied to system size or performance.

– Tax credits and accelerated depreciation (where applicable): Lower net cost for homeowners and certain organizations.

– Net energy metering or export tariffs: Compensate for electricity delivered to the grid, with rates that vary by region and time of day.

– Low-interest loans or green financing: Make cash flow positive sooner, especially where utility rates are high.

– Performance-based incentives: Reward actual energy production rather than nameplate capacity.

Consider a simplified example. A 7 kW system at $3.00 per watt totals $21,000 before incentives. If local programs shave 30% off the price, the net cost becomes $14,700. Assume it produces 9,800 kWh annually and your blended electricity rate is $0.22 per kWh; that’s about $2,156 in avoided purchases in the first year. Even after accounting for modest losses, rate changes, and degradation, simple payback could land around 6–8 years, with decades of useful life remaining after costs are recovered. If rates escalate, savings may accelerate; if export rates are lower than retail, storage or load shifting can boost self-consumption and value. This math is sensitive to local tariffs and system design, so a site-specific proposal is worth the time. Still, the general trend is clear: as equipment prices have declined and power prices have risen in many areas, solar has become a financially compelling addition to roofs that see regular sun.

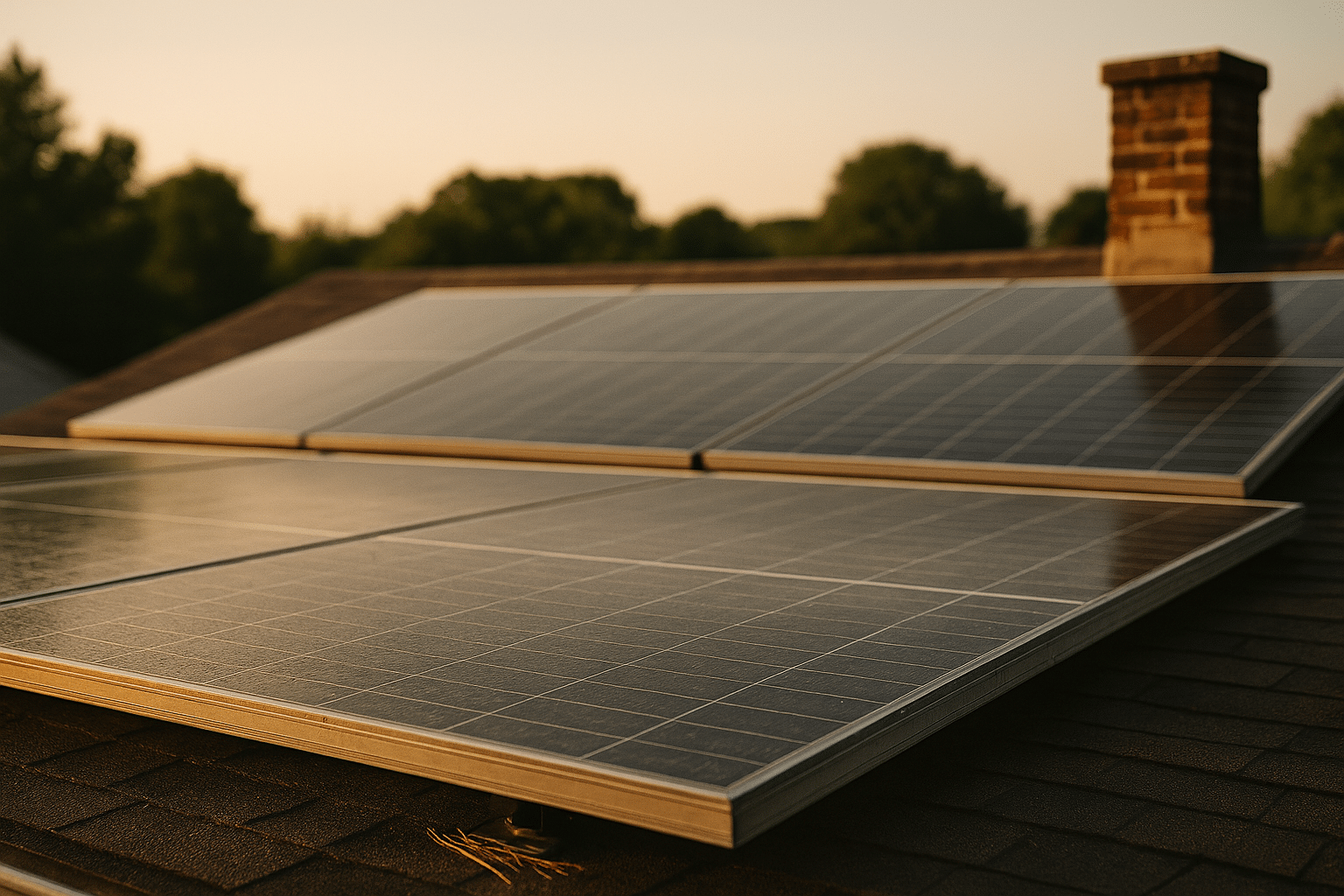

Installation, Siting, and Maintenance

Turning a concept into a functioning array starts with a site assessment. A designer will map roof planes, measure available area, and calculate potential shading over the year using sun-path tools. Structural considerations matter: rafters, trusses, and roof decking must comfortably handle added loads from racking, modules, wind, and occasional snow. Roofing material plays a role too; asphalt shingles are straightforward, metal standing seam can be elegant with fewer penetrations, and tile may require specialized attachments. Electrical layout includes safe conductor routing, labeling, grounding, and shutoff equipment to comply with codes and utility interconnection rules. Thoughtful placement of the inverter and any batteries—ideally in cool, shaded, accessible locations—simplifies maintenance and prolongs component life.

A practical pre-install checklist might include:

– Confirm roof condition and remaining lifespan; replacing an aging roof before solar can prevent future rework.

– Verify structural capacity or consult an engineer for heavier loads or unusual spans.

– Map setbacks, vents, chimneys, and skylights to avoid conflicts and fire-code clearance issues.

– Plan for wiring paths, conduit aesthetics, and service disconnect placement.

– Obtain required permits and clarify utility metering and interconnection timelines.

Once installed, upkeep is light but not nonexistent. Dust, pollen, bird droppings, or urban grime can accumulate; in many climates, rain does the cleaning, but a gentle rinse during dry seasons can help. Avoid abrasive tools that might damage coatings. Annual or semiannual inspections—visual checks of wiring, connectors, and roof penetrations—can catch issues early, such as a loose clamp or a cracked seal. Wildlife guards may deter nesting under arrays. In snowy regions, it is usually safer to let snow slide off naturally rather than attempt manual removal. Inverters may need replacement or servicing after 10–15 years, while modules often continue reliably for 25 years or more. Keeping a monitoring system active provides early warning of string outages, arc-fault trips, or anomalous dips in production. Treat the array like a quietly valuable appliance: a little attention, now and then, goes a long way.

Environmental Impact and Future Trends

Solar’s environmental story is rooted in low operational emissions and improving manufacturing practices. Lifecycle assessments typically place photovoltaic electricity in the range of roughly 20–60 grams of CO2-equivalent per kWh, varying by technology and factory energy mix—substantially below gas-fired generation and far below coal. Energy payback time—the period needed for a system to generate the energy used to make it—often spans 1–3 years in sunny locations. After that, the array is a net contributor for decades. Materials matter too: aluminum frames are highly recyclable, glass is abundant, and silicon cell production has become more efficient. Attention is turning toward reducing the use of scarce metals and designing for disassembly so that future recycling recovers more valuable components.

Responsible end-of-life management is gaining traction. Dedicated recycling facilities are expanding, with processes that separate glass, metals, and silicon for reuse. Policymakers in several regions are developing rules to fund collection and recycling, reducing the risk that modules become e-waste. Thoughtful procurement can favor manufacturers that publish environmental product declarations or adopt closed-loop initiatives. For most homeowners, selecting durable equipment and ensuring proper documentation of serial numbers, installation dates, and warranties will simplify eventual recycling and warranty service.

Looking ahead, several trends are reshaping rooftops and fields:

– Smarter inverters and grid services: Voltage support, frequency response, and remote updates help stabilize modern grids with more renewables.

– Pairing with storage: Batteries increase self-consumption, provide backup, and shift solar energy into evening peaks.

– Community and shared solar: Expands access for renters or shaded homes by offering subscriptions to offsite arrays.

– Agrivoltaics and dual land use: Panels elevated over crops or pasture can reduce heat stress and conserve water while producing electricity.

– Advanced materials: Tandem cells that stack absorbers may lift efficiencies, while building-integrated PV blends power production into facades.

The arc of innovation is steady rather than flashy. Efficiency gains arrive in small, reliable increments; manufacturing footprints shrink; and software wrings more value from each watt. For households and organizations, the upshot is a technology that slots more neatly into everyday life year after year. Solar won’t solve every energy challenge alone, but as part of a broader toolkit—including efficiency, smart controls, and storage—it offers a durable path toward cleaner, more resilient power.

Conclusion: Turning Sunlight into a Practical Plan

If you’re weighing solar, start with a candid look at your roof, your utility rates, and your goals—lower bills, resilience, or a lighter environmental footprint. Ask for site-specific estimates that include production, incentives, and clear assumptions, and compare options that balance efficiency, durability, and cost. A solid design paired with straightforward maintenance can deliver dependable energy for decades. With the right plan, those quiet rectangles overhead can become a steady ally in your daily life, converting everyday sunshine into meaningful savings and cleaner electricity.