Solar Panel Installation: Planning, Permits, Costs, and Maintenance

Outline

– Assess your site and determine a suitable system size

– Understand permits, codes, and interconnection steps

– Compare equipment and mounting methods for your roof

– Model costs, incentives, and financing paths

– Learn the installation process, commissioning, and maintenance

From Sunlight to System Design: Site Assessment and Sizing

Great solar projects begin on the ground with a tape measure, a compass, and a candid look at your home’s energy use. Start by gathering a year of electric bills to capture seasonal swings. Average daily consumption in many homes ranges from 15 to 35 kWh, but the right target depends on usage, future plans (an electric vehicle, heat pump, or home office), and local electricity pricing. A rule of thumb for roof space is that 1 kW of modules typically occupies about 65–100 square feet, depending on panel wattage and layout. With modern modules around 380–450 W each, a 6 kW system often needs 14–18 panels and roughly 280–500 square feet of clear, unobstructed area.

Solar potential hinges on sun access. Roofs facing south in the northern hemisphere (north in the southern hemisphere) deliver strong yield, while east/west orientations often trim output by about 5–15% compared with an ideal azimuth. Tilt angles close to your latitude are efficient, yet most pitched roofs perform well without tilt adjustments. The real enemy is shade. Even partial shade near solar noon can reduce annual energy significantly; design for annual shading losses under 10% when possible. Use smartphone sun‑path tools or a professional shade analysis to check trees, chimneys, and nearby structures. If shade is unavoidable, favor inverter options that localize and mitigate losses across modules.

Climate also shapes expectations. Annual energy from 1 kW of solar can range roughly:

– 1,500–1,900 kWh in sunny regions with high irradiance

– 1,100–1,400 kWh in temperate areas

– 900–1,200 kWh in cloudier or high‑latitude zones

A 6 kW array might therefore produce about 5,400–11,400 kWh per year depending on location and design. That range helps you estimate how much of your current usage solar could offset and whether future electrification plans call for extra capacity.

Finally, verify the roof and structure. Solar adds modest weight—commonly 2–6 pounds per square foot for roof‑mounted systems—plus wind and snow loads. Many jurisdictions require an engineer’s letter to confirm the roof can handle it. Check roof age; installing on a roof with less than 5–10 years of life left can lock in higher future costs, because removing and reinstalling a system later adds complexity. Thoughtful sizing considers both today’s bills and tomorrow’s ambitions, balancing available roof space, budget, and the energy curve of your household.

Permits, Codes, and Interconnection: Clearing the Paper Trail

Solar projects succeed not only on rooftops but also at the permit counter and utility portal. Most areas require an electrical permit and a building permit; some add zoning or historic approvals. The submittal package typically includes a site plan, a roof layout with fire‑department access pathways, a structural letter if needed, and an electrical single‑line diagram showing conductors, overcurrent protection, grounding, and disconnects. Rapid‑shutdown and arc‑fault protection are common code requirements for residential rooftop systems, and labeling conventions are often prescribed down to color and wording. While specifics vary by jurisdiction, accurate drawings and compliant equipment datasheets speed approvals.

Fire and building codes frequently require clear roof setbacks at ridges, hips, and eaves to maintain safe access for firefighters. These pathways influence how many modules fit and can determine whether an array is split into multiple sub‑arrays. Electrical codes govern conductor ratings, conduit fill, working clearances, and bonding of metal components. Expect the authority having jurisdiction (AHJ) to review structural loads for wind and snow and to confirm attachment methods match manufacturer instructions. A tidy, code‑consistent design reduces back‑and‑forth and shortens review cycles.

Utility interconnection is its own track. You will usually submit:

– An application with system size and equipment lists

– A single‑line diagram and site plan

– Proof of property ownership or authorization

– Insurance or certifications if required

Approval times range from about 1–8 weeks, depending on the utility’s workload and grid conditions. Export compensation varies: some areas credit exported energy at retail rates, others use time‑varying credits or fixed export rates. Be sure you understand whether credits roll over monthly or annually and whether there are caps on system size relative to your historical usage.

After permits are issued and the system is installed, the AHJ performs inspections to verify code compliance. The utility may conduct a separate inspection, a meter swap, or a witness test to confirm anti‑islanding behavior and protective settings. The final milestone is “permission to operate” (PTO), which allows you to energize the system in parallel with the grid. Realistic planning for approvals—often 2–10 weeks in total—keeps expectations grounded and helps you schedule installation during favorable weather windows.

Hardware Choices and Mounting Methods: Panels, Inverters, and Roofing Realities

Equipment decisions shape performance, aesthetics, and maintenance. Most homeowners compare monocrystalline modules with higher efficiencies (often ~19–22%) to standard options that may land around 16–18%. Higher‑efficiency modules reduce roof area for a given system size but can carry a premium. Temperature coefficient matters: modules with a lower negative coefficient (for example, around −0.34%/°C) retain more output on hot days. Warranties typically include 10–25 years for product and up to 25–30 years for performance, with allowable degradation often tapering from a few percent in year one to roughly 0.25–0.7% annually thereafter. Glass quality, frame stiffness, and robust junction boxes contribute to longevity, especially in windy or coastal climates.

Inverter architecture is equally consequential. Three common approaches are:

– String inverters: economical, straightforward, centralized maintenance; production can be affected by shade across a string.

– Microinverters: module‑level conversion, granular monitoring, strong shade tolerance; more units on the roof can mean more distributed points of service, though failures are localized.

– DC optimizers with a string inverter: hybrid model with module‑level power conditioning and centralized AC conversion; helpful on complex roofs.

Choosing among them involves roof complexity, shade patterns, monitoring preferences, and budget. Many designers “oversize” DC relative to the inverter’s AC rating (e.g., a DC/AC ratio of 1.1–1.4) to improve annual energy capture without significantly increasing losses at peak.

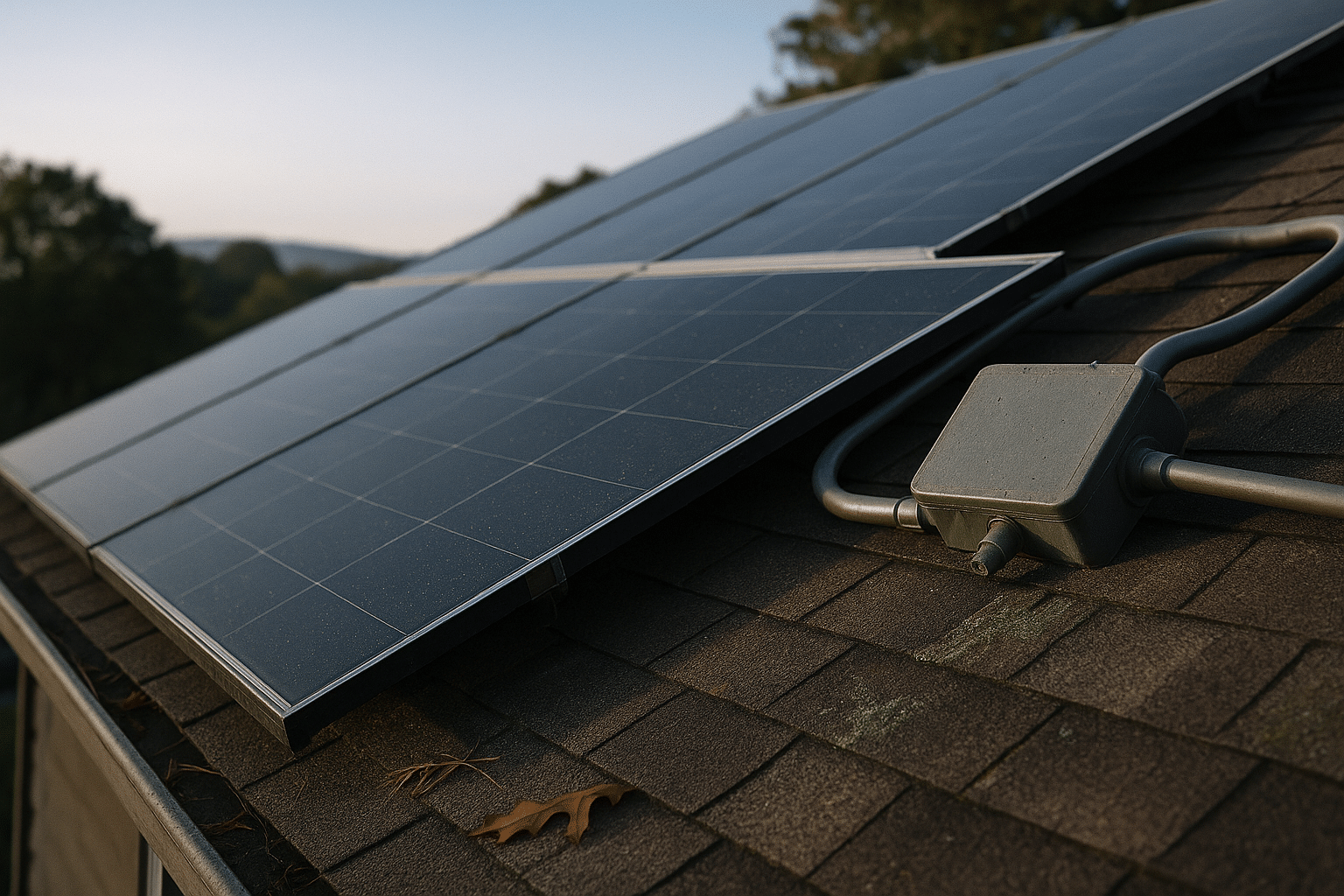

Mounting must respect the roof. On asphalt shingles, flashed lag screws into rafters with metal flashing and butyl seals are common. On standing‑seam metal, non‑penetrating clamps that attach to the seams provide elegant, low‑hole solutions. Tile roofs often use hooks or replacement flashing bases to bridge fragile tiles while anchoring into the structure below. Flat roofs may use ballasted racking that rests on the membrane with wind deflectors, sometimes supplemented with anchors where uplift is intense. Ground mounts suit larger properties; fixed‑tilt frames are simple and sturdy, while single‑axis trackers add yield but raise cost and mechanical complexity.

Small details keep systems reliable. Use UV‑resistant cable clips to secure conductors under modules, avoid drip loops that invite water ingress, and keep conduit runs neat with accessible service loops. Bond and ground metallic parts per code, add surge protection at critical points, and consider snow guards where sliding snow could damage gutters. In storm‑prone zones, structural attachments and spacing must reflect local wind maps, and in coastal areas, hardware with corrosion‑resistant coatings is prudent. The most elegant system is the one that quietly endures for decades, even when the weather forgets to be friendly.

Costs, Incentives, and Financing: Turning Numbers Into a Plan

Understanding the money side is empowering. Residential turnkey pricing frequently ranges around $2.20–$3.50 per watt before incentives, depending on region, roof complexity, equipment choices, and labor market conditions. A 6 kW system at $2.60/W would total about $15,600 before incentives. Incentives can dramatically alter the net price. Many regions offer a mix of tax credits, point‑of‑sale rebates, and performance‑based payments. In the United States, a federal income tax credit has been set at up to 30% for qualifying residential systems during certain years; local and state programs may stack on top. Always confirm current eligibility rules, step‑downs, and caps.

Look beyond sticker price to value. A simple payback period (net cost divided by annual bill savings) often lands in the 6–12 year range, shifting with electricity rates, solar resource, and financing terms. A more complete view is levelized cost of energy (LCOE). For example, if a 6 kW array produces 8,000 kWh annually for 25 years (200,000 kWh lifetime) and the net installed cost is $12,000 after incentives, the LCOE is roughly $0.06 per kWh, excluding maintenance. Compare that to your utility’s current and expected rates, and remember that many households electrify more loads over time, increasing the value of on‑site generation.

Financing changes the math:

– Cash: lowest long‑term cost, full ownership, access to incentives.

– Loan: spreads payments, interest adds cost; ownership and incentives remain with you.

– Lease or power purchase agreement: little or no upfront payment; a provider owns the system and you buy the energy or pay a fixed fee; incentives typically flow to the provider.

When evaluating offers, line up key assumptions: system size (kW), guaranteed or estimated annual production (kWh), escalators on payments, and what happens if you sell the home. Request itemized proposals so you can compare apples to apples—modules, inverters, racking, monitoring, balance‑of‑system parts, labor, permits, inspections, and overhead.

Maintenance expenses are modest but real. Budget for occasional cleaning in dusty areas, potential pest screening, and an inverter replacement within 10–15 years depending on model type and warranty coverage. Roof work during the system’s life can also add costs for temporary removal and reinstallation. By modeling both upfront and lifecycle costs, you’ll be prepared to choose a system that fits your budget today and remains economical as energy prices evolve.

Installation, Commissioning, and Maintenance: What Happens After You Sign

Once design and permits are in hand, the build proceeds in orchestrated steps. Installers lay out attachment points over rafters, drill pilot holes, apply sealant, and set flashed or clamped mounts. Rails are leveled and square, then modules are placed and wired according to the string plan or module‑level scheme. Conduits route DC or AC safely to a disconnect and service panel, with proper labeling and clear working spaces. Many crews finish a typical residential install in one to three days, weather and roof complexity permitting. Quality assurance includes torque checks on hardware, visual inspection of cable management, and confirmation that penetrations are properly sealed.

Commissioning verifies performance and safety. Technicians check open‑circuit and operating voltages, polarity, insulation resistance, and ground continuity. If applicable, rapid‑shutdown functions are tested. Monitoring is configured so you can see daily production and receive alerts. After jurisdictional and utility inspections, the utility grants permission to operate. Expect:

– Authority inspection(s) for code compliance

– Utility meter upgrade or swap

– PTO notice before the system runs in parallel

Once live, you can watch production curves change with seasons and weather, a small thrill that never quite gets old.

Maintenance focuses on prevention rather than constant attention. Annual or biannual visual checks for loose conductors, worn clips, or debris around mounts go a long way. In dusty or pollen‑heavy regions, a gentle rinse during cool mornings can restore output; avoid harsh chemicals and high‑pressure jets that may damage seals. Keep records of production; a quiet drift below historical averages can flag shading from new tree growth, a failing inverter channel, or accumulated soiling. Common tasks include:

– Clearing leaves, seed pods, and nesting debris from under arrays

– Inspecting roof seals after severe storms

– Confirming monitoring stays connected after router or modem changes

Over decades, components age. Module performance degrades slowly, often around a fraction of a percent per year, while inverters may need replacement within the system’s life—plan for that in your financial model. If a roof replacement arises, coordinate a remove‑and‑replace with the solar crew so mounts and rails return to engineered positions. Safety remains paramount: always isolate power, follow lockout/tagout procedures, and consult qualified professionals for electrical work. With a clean design, solid installation, and periodic checkups, a solar array can deliver reliable energy through heatwaves, cold snaps, and everything between.