2026 Guide to High-Demand Trade Schools & Career Certification

Outline and Why Skilled Trades Matter in 2026

Skilled trades are having a moment, and 2026 looks set to extend that momentum. Building retrofits, efficient heating and cooling, grid upgrades, and the spread of automation are creating steady demand for people who can install, wire, test, and maintain real equipment. While some sectors chase uncertain trends, the trades convert physical work into measurable outcomes: a system runs, a circuit passes inspection, a plant restarts. Rapid training, clear certifications, and concrete hiring pipelines make this space uniquely practical for career changers and recent graduates alike.

Outline of this guide:

– Section 1 frames the labor context and explains how we evaluate programs, using employer needs and licensure pathways as anchors.

– Section 2 profiles high-demand vocational programs for 2026, with examples of tasks, learning modules, timelines, and common certifications.

– Section 3 breaks down what “top-rated” HVAC and electrical technician schools tend to share, with a comparative lens on public, technical, and private options.

– Section 4 offers a step-by-step method to choose a school for rapid employment, including due diligence scripts and ROI math.

– Section 5 ends with a practical 90-day action plan to move from research to enrollment to early hire opportunities.

Method notes and what matters: We prioritize programs that align with state licensing requirements, recognized safety training, and third-party exam eligibility. We emphasize lab intensity, supervised practice on modern equipment (including heat pump systems, variable-speed drives, and energy-management controls), and structured work-based learning such as internships or pre-apprenticeships. Where exact job growth numbers vary by region, hiring signals are remarkably consistent: employers seek readiness with tools, comfort reading schematics, safe work habits, and the ability to document and communicate repairs. A final point: choose schools that publish outcomes—placement rates, exam pass rates, and employer partner lists—so your decision rides on evidence, not slogans.

High-Demand Vocational Training Programs for 2026

Several training paths stand out for 2026 because they connect directly to infrastructure, energy efficiency, and manufacturing resiliency. These programs typically span a few months to under two years and focus on measurable competencies rather than abstract theory. If you want a career where the learning is hands-on and the outcome is a job that cannot be shipped overseas, these tracks are worth a close look.

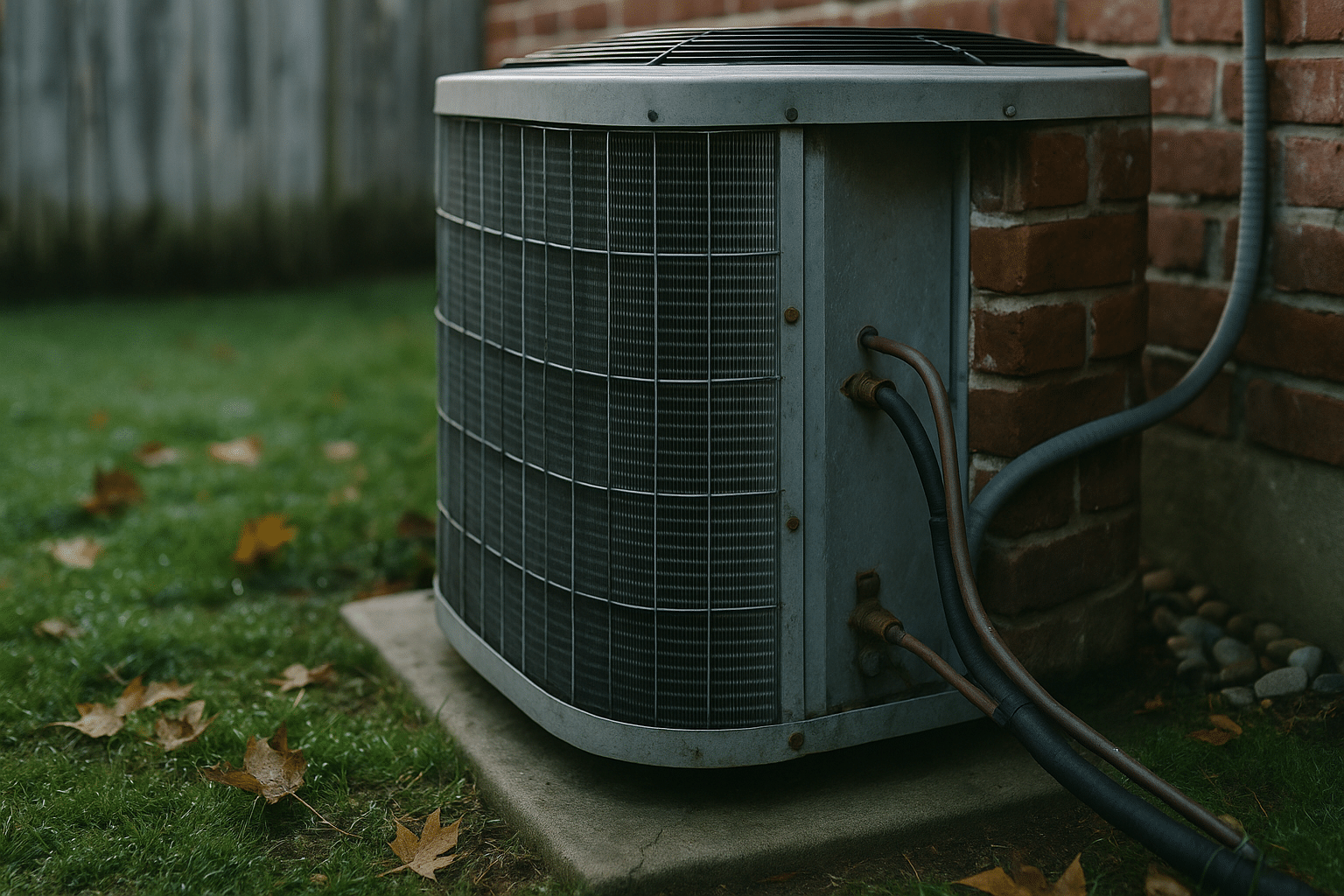

HVACR Technician (heating, ventilation, air conditioning, refrigeration):

– Why demand is strong: efficiency upgrades, heat pump adoption, data center cooling, and building retrofits.

– Core skills: refrigeration cycle diagnostics, airflow balancing, brazing, electrical controls, heat pump commissioning.

– Certifications: federal refrigerant handling certification for working with controlled refrigerants; many regions recognize additional voluntary technician credentials.

– Typical timeline: 6–18 months plus paid hours to reach higher technician tiers.

– Day-to-day tasks: diagnose temperature or pressure faults, replace components, evacuate and recharge systems, and document service in work orders.

Electrical Technician:

– Why demand is strong: construction, service upgrades, distributed energy, low-voltage systems, and industrial maintenance.

– Core skills: wiring methods, conduit bending, motor controls, code-compliant installations, testing with meters and insulation testers.

– Licensing: state-specific trainee, apprentice, and journeyman steps; classroom hours often count toward exam eligibility.

– Timeline: 9–24 months of school plus supervised field hours.

– Day-to-day tasks: install branch circuits, troubleshoot control panels, verify grounding and bonding, and coordinate inspections.

Solar and Energy Storage Installer:

– Why demand is strong: rooftop and commercial arrays, backup power, and resilience projects.

– Core skills: array layout, racking, string sizing, inverter commissioning, storage integration, and interconnection paperwork.

– Suggested add-ons: electrical code coursework and fall-protection safety.

Industrial Maintenance/Mechatronics:

– Why demand is strong: lean manufacturing, automation, and uptime requirements.

– Core skills: sensors, pneumatics, hydraulics, drives, conveyors, PLC fundamentals, and preventive maintenance.

– Typical graduates move into multi-skill tech roles supporting production lines.

Welding and Fabrication; Plumbing; Building Automation Systems:

– These roles support large and small projects alike, from pipelines and structural frames to smart buildings and water efficiency.

– Each offers stackable credentials and a ladder from entry-level helper to specialist.

Across these tracks, employers consistently reward graduates who can read drawings, follow safety procedures, use digital service tools, and communicate clearly with clients and inspectors. Your goal is simple: choose a program that turns these competencies into muscle memory through well-run labs and structured practice.

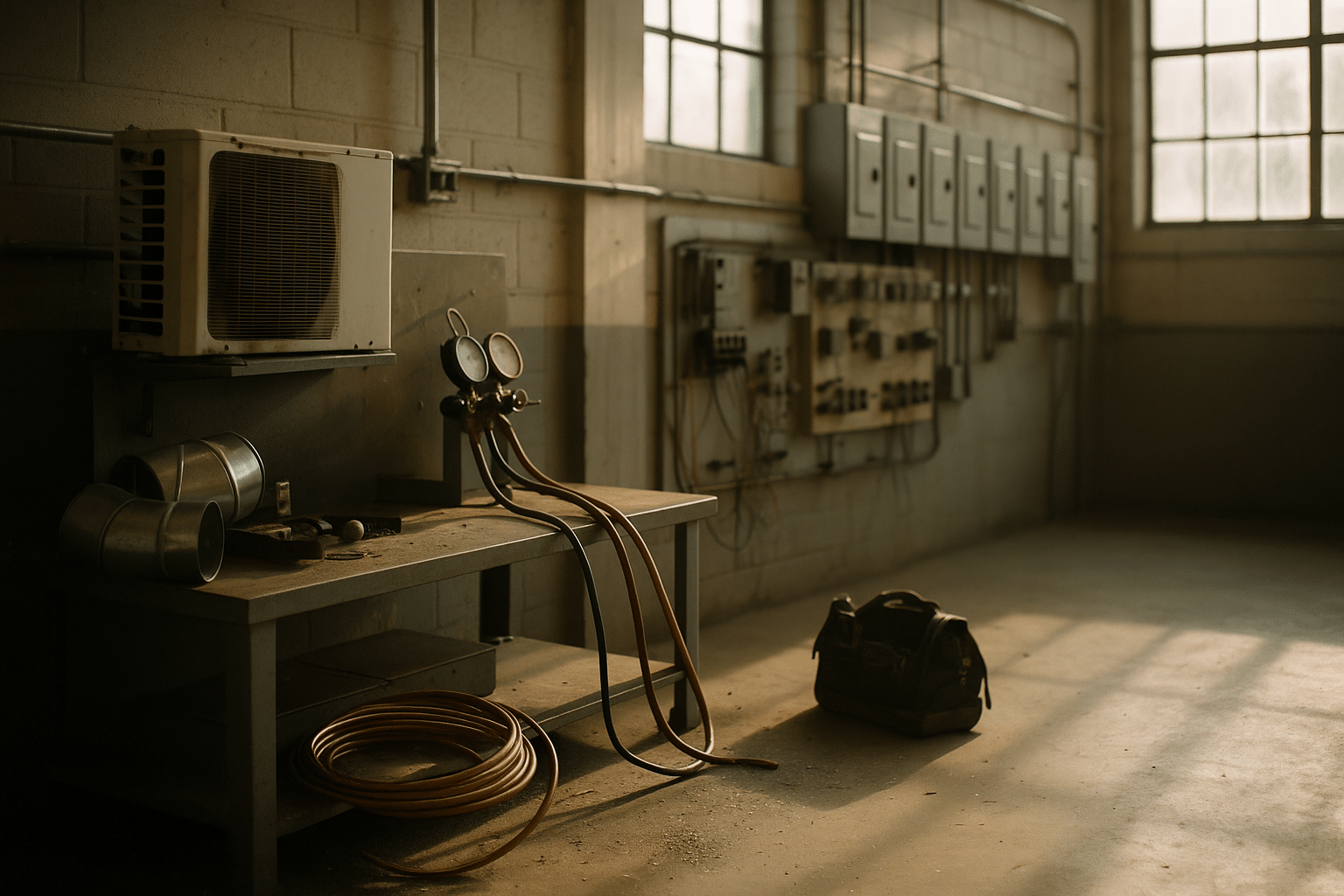

Top-Rated HVAC and Electrical Technician Schools: What They Share

“Top-rated” in the trades is not about glossy brochures; it is about verifiable outcomes and the realism of the training environment. High-quality HVAC and electrical programs tend to blend classroom clarity with lab intensity, and they make it easy to transition from school to paid hours. Think of the program as a bridge: the sturdier its supports—accreditation, safety, modern equipment, and employer ties—the smoother your crossing.

Common traits of standout HVAC and electrical schools:

– Accreditation that ensures federal aid eligibility and credit transfer options, plus compliance with recognized academic standards.

– Clear licensure and certification mapping: electrical code coursework tied to state requirements; refrigerant handling preparation included in tuition.

– High lab-to-seat ratio: small cohorts on real equipment—heat pumps, economizers, variable-refrigerant systems, motor control trainers, and service simulators.

– Documented outcomes: placement rates, exam pass rates, average time to first job, and sample roles graduates secure.

– Employer partnerships: advisory boards, equipment donations, guaranteed interview days, and supervised internships.

– Safety culture: 10- or 30-hour construction safety cards and lockout/tagout procedures practiced in lab, not just read in a manual.

How different school types compare:

– Public community colleges: often affordable, strong support services, robust labs, and credit-bearing pathways that can stack into further credentials; schedules may be semester-bound.

– State technical institutes: concentrated trade focus, frequent intakes, and tight industry links; good for learners seeking rapid immersion.

– Private accelerated academies: intensive timelines, night/weekend options, and frequent employer visits; evaluate cost-versus-outcomes carefully and verify refund policies.

Simple scoring model you can use:

– Employment outcome (40%): placement within 90–180 days after graduation.

– Certification and exam success (25%): pass rates and number of graduates earning required credentials.

– Lab capacity and equipment freshness (20%): ratio of students to workstations and presence of current-generation systems.

– Employer engagement (15%): advisory boards, internship slots, and on-site interviews.

Red flags:

– Vague claims about job guarantees without clear terms.

– Outdated labs lacking modern controls or heat pump systems.

– Hidden fees for exams, tools, or safety cards.

– No published outcomes or unwillingness to connect you with recent graduates.

How to Choose the Right Trade School for Rapid Employment

Speed matters, but so does fit. Rapid employment comes from aligning your program with local demand, licensure steps, and a schedule you can sustain. Use this practical sequence to turn research into a confident enrollment and a job-ready exit.

Step 1: Define your target role and region.

– Identify two roles you would accept (for example, residential HVAC service tech or commercial installer; electrical service tech or low-voltage specialist).

– Pull 20 local job postings and list the recurring requirements: hours, certifications, tools, and software mentioned.

– Note any state rules on trainee cards, supervised hours, or exam prerequisites.

Step 2: Shortlist three schools and pressure-test outcomes.

– Ask for a written syllabus mapping each course to job tasks and required credentials.

– Request outcome data: placement rate, average starting range by role, time to first job, and third-party exam pass rates.

– Speak with two recent graduates and one employer who actively hires from the program.

Step 3: Inspect the labs and observe a class.

– Count workstations and compare to cohort size; watch how instructors circulate and assess.

– Look for modern heat pump setups, variable-speed drives, control panels, and diagnostic tools that match current jobsite gear.

– Confirm that safety procedures are practiced hands-on, including lockout/tagout and fall protection where relevant.

Step 4: Map licensing and certifications.

– HVAC: ensure the program includes preparation and proctoring for federal refrigerant handling certification and covers commissioning practices.

– Electrical: verify hours count toward your state’s apprentice or journeyman pathway and that code instruction matches the current code adopted locally.

– Solar/storage add-ons: check that interconnection rules and commissioning steps are taught for your utility region.

Step 5: Calculate ROI and funding.

– Quick math: Net cost = tuition + fees + tools − grants − employer tuition support.

– Payback estimate = Net cost / (expected monthly take-home increase).

– Example: If net cost is 8,500 and monthly take-home rises by 900, payback is roughly 9–10 months.

– Ask about payment plans, grants, work-study, and tool lending libraries to limit upfront cash.

Step 6: Secure early work exposure.

– Seek pre-apprenticeship slots, part-time helper roles, or internships built into the program.

– Aim for a pre-hire interview before graduation by attending employer days and presenting a small portfolio: lab checklists, photos of your builds, and instructor evaluations.

The right school answers hard questions with transparent data, shows you equipment that mirrors the field, and introduces you to the companies that will soon read your resume. When those pieces line up, employment accelerates.

Conclusion and a 90-Day Action Plan

If you are aiming for a practical career pivot in 2026, trade training offers a direct route from classroom to a paycheck. The opportunity is real because demand is anchored in physical work that keeps homes comfortable, facilities running, and the grid resilient. Success, however, is not automatic. It comes from selecting programs that publish outcomes, teach on current gear, and build bridges to employers through structured work experience and recognized certifications.

Here is a 90-day action plan to move decisively:

– Days 1–7: Collect 20 local job postings in your target field and extract the recurring requirements. Create a one-page target profile listing must-have skills and certifications.

– Days 8–14: Identify three schools within commuting range (or hybrid options) and schedule tours. Ask for syllabi and outcome sheets. Request two graduate contacts per school.

– Days 15–21: Visit labs. Watch a class in action. Confirm lab-to-seat ratio, safety practice, and the exact equipment you will use.

– Days 22–28: Verify licensing alignment and exam preparation. Request written confirmation that your classroom hours count toward state requirements, where applicable.

– Days 29–42: Apply for funding: grants, payment plans, tool assistance, and any employer-sponsored tuition support. Lock in test dates for required certifications.

– Days 43–60: Start bridge learning: safety modules, basic electrical theory, refrigeration fundamentals, and measurement skills so you hit the ground running.

– Days 61–75: Attend employer events. Target a pre-hire interview. Assemble a portfolio with lab checklists, photos of builds, and references.

– Days 76–90: Finalize enrollment. Align class times with a part-time helper role to begin accumulating supervised hours and real references.

Think of this plan as a jobsite layout: clear measurements, the right tools, and a sequence that prevents rework. By focusing on outcomes, equipment realism, and employer access, you turn training into traction. When the switch flips on your first service call or the airflow numbers land in spec, you will know the preparation paid off—and that you chose a pathway designed for durable, in-demand work.